Impact of zirconium incorporation on the thermophysical properties of uranium mononitride

The paper link is here.

Elina Charatsidou, Anita Pazzaglia, Kaitlyn Bullock, Maria Giamouridou, Eleanor Lawrence Bright, Mikael Jolkkonen, Christoph Hennig, Pär Olsson

Highlights

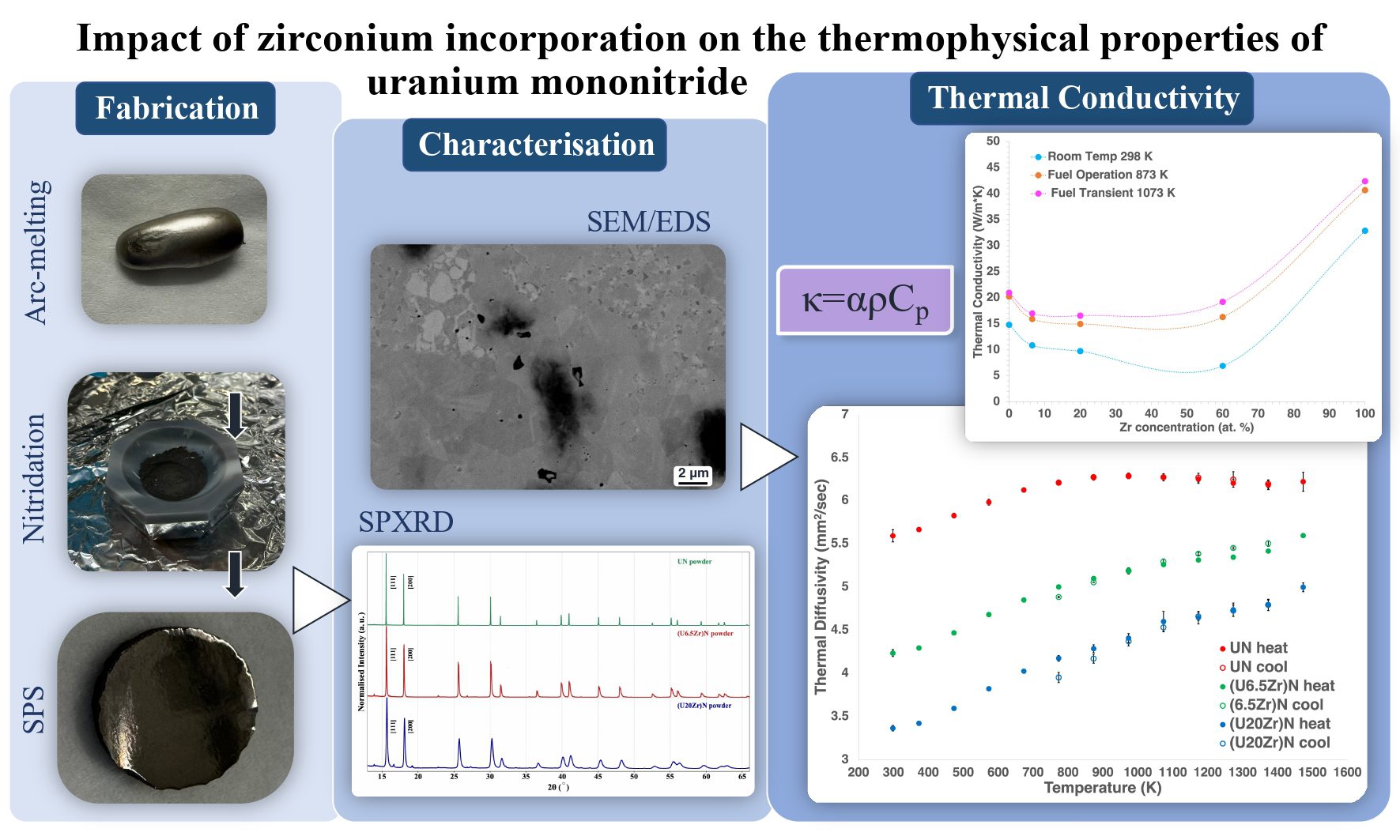

- Spark plasma sintering (SPS) yields improved solid-solution homogeneity in (U,Zr)N pellets compared to mixed powders.

- Zr incorporation systematically reduces thermal conductivity of UN.

- The (U,Zr)N microstructure does not meet the requirements for percolative heat transfer.

- Thermal conductivity degradation saturates at moderate Zr concentrations.

- Zr increases the high-temperature slope of thermal conductivity compared to UN.

Abstract

Uranium mononitride (UN) is a promising candidate fuel for next-generation fast reactors due to its high fissile density, superior thermal conductivity, and high melting point compared to conventional oxide fuels. However, scarce experimental data on UN and its thermophysical behaviour under fission product incorporation limits its performance assessment. Zirconium nitride (ZrN) is an efficient thermal conductor and a candidate material for inert matrix fuels. Given its high thermal conductivity, ZrN addition at sufficient concentrations should, in principle, induce percolation conduction and increase thermal conductivity in UN. To decouple chemistry from irradiation-induced porosity, known to dominate thermal degradation at high burnup, this study isolates the intrinsic chemical contribution of Zr incorporation under dense, low-porosity conditions. (U,Zr)N pellets with 6.5 and 20 at. % Zr were fabricated by spark plasma sintering (SPS), using powders produced from arc-melted alloy via the hydride-nitride-denitride route. Synchrotron powder X-ray diffraction confirmed the formation of solid solutions and enhanced Zr solubility after sintering, resulting in improved microstructural homogeneity. Thermal diffusivity was measured between 300 and 1500 K using light flash analysis, and thermal conductivity was derived using heat capacity and density correlations with porosity correction. Despite the intrinsically higher thermal conductivity of ZrN, the incorporation of 6.5 at. % Zr reduced the thermal conductivity relative to UN, consistent with impurity scattering. The 20 at. % Zr composition further decreased conductivity, indicating the microstructure does not meet the conditions required for percolation conduction. Differences in the temperature dependence of thermal diffusivity between UN and Zr-bearing samples highlight a compositional influence on heat transport. The results provide benchmark data for (U,Zr)N and insights into chemical and thermophysical interactions in nitride ceramics.